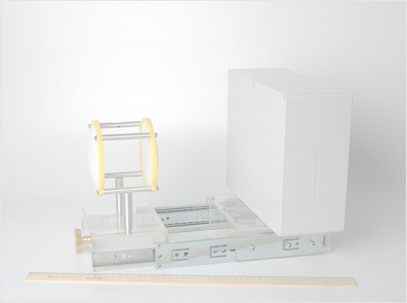

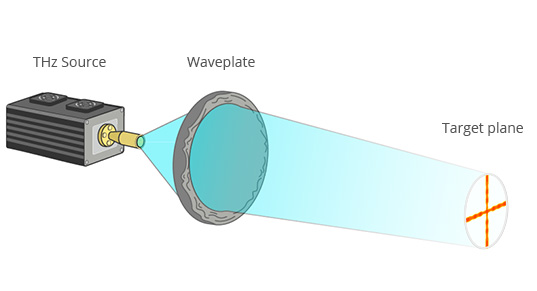

TeraSense has developed and patented a ground-breaking technology for making new-generation semiconductor imaging systems for Terahertz (THz) and sub-THz frequency ranges. TeraSense devices bridge the gap of 0.1 – 1.0 THz since exploiting this particular frequency band has been arousing increasingly more interest as it opens far-reaching possibilities for creating the state-of-the-art visualization solutions to meet the growing demand for sophisticated yet cost-effective instrumentation. Owing to its harmless and versatile nature, there is whole host of viable practical applications of THz imaging technology to be realized, from nondestructive industrial product quality control in manufacturing and agriculture to noninvasive medical diagnostics and security screening. The use of THz devices will undoubtedly proliferate in the nearest future as this innovative technology is imminently coming to take its due place in many areas of our lives.TeraSense custom-builds complete fully-operational terahertz imaging systems equipped with software and all necessary hardware components, including a camera with 2D sensor array, one or more signal generators with output horn antennas and complementary optics. Using discrete modules allows to adapt the system to meet desired specifications of operating frequency, power level, physical shape and dimensions of the detector area and overall geometrical configuration. What is more, due to their compact size and functional flexibility, TeraSense imaging systems can be easily integrated into more elaborate industrial solutions.

Terahertz imaging

TeraSense fabricates low-cost 2D semiconductor sensor arrays scalable to match required shape and dimensions, from a square to a linear matrix, with available pixel sizes of 0.5×0.5, 1.5×1.5 and 3.0×3.0 millimeters. These arrays are utilized to construct cost-effective, highly sensitive and exceptionally compact terahertz cameras capable of ultra-fast registration rate of up to 5000 fps. As this novel technology presently outranks any competition, it has great potential to become an expedient element in a broad scope of hi-tech applications, such as

-THz non-destructive testing

-Security screening

-Medical imaging (THz tomography)

-Terahertz communication

Terahertz signal generation

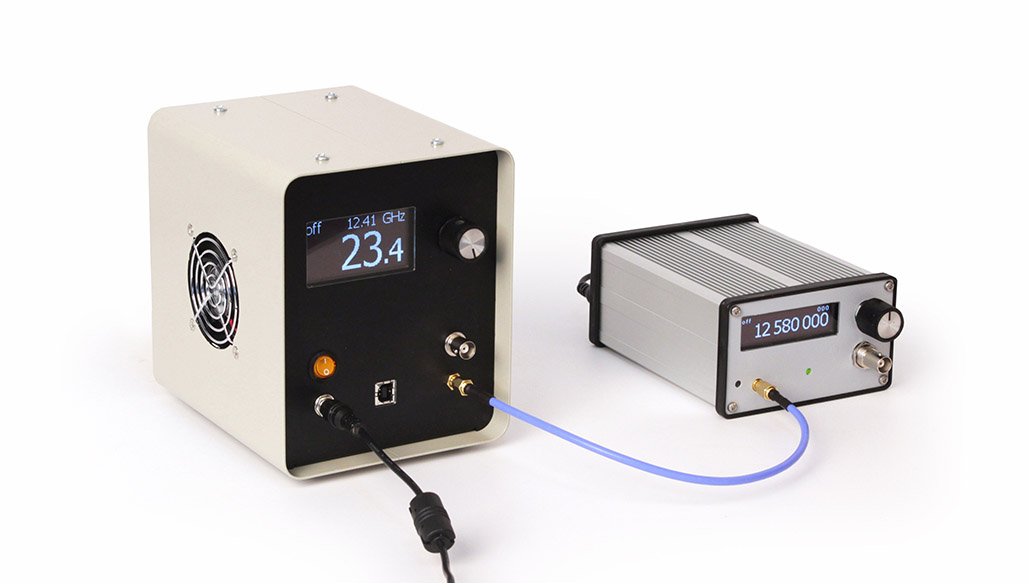

For the terahertz signal generation purposes TeraSense makes use of proprietary IMPATT and Schottky-diode technologies. Designed to operate in sub-terahertz frequency range of 0.1 – 0.3 THz, these cutting-edge devices are currently some of the most powerful solid-state THz sources on the market that have capacity to generate a continuous Wave (cw) signal with output power level of up to 0.5 W. All TeraSense generators boast exceptionally long life of fully stable and reliable operation. Moreover, it is their remarkably compact size and low cost that put these devices in the vanguard of the competition. All these advantages imply numerous possibilities in terms of both small and large-scale applications as they enable straightforward integration of TeraSense sources as stand-alone units into complex industrial systems.

Medium-gain horn

High-gain horn

We all know that homeland terror knows no bounds and is currently on the rise. What’s more, terror methods are becoming more ingenious with hidden weapons and threats which are hard to detect. Security-related applications can be subdivided into two major subcategories outlined below.

Security screening of letters, envelopes and small packages

Detecting powder, liquids, explosives and other threats in small packages and mail has recently become highly important. After discovering letters containing anthrax, such new threats as CBRE (chemical, biological and radiological elements) are perceived as real and requiring new and effective detection approaches to counter them. Designed for inspecting flat objects (envelopes, letters, small packages), our Terahertz imaging scanner offers a brand-new approach for security screening in terms of safety, accessibility and detection.

Read more about terahertz security applications

Security screening of people (body scanner)

Unlike X-ray machines, Terahertz waves are completely harmless for humans and have no ionizing radiation, but can easily penetrate clothes and some other enclosures. These properties make THz-based people screening solutions extremely valuable for applications where human health and safety are of utmost importance.

The TeraSense security body scanner operates in reflection mode and is intended for stand-off detection of weapons, including cold steel and firearms, bombs and grenades, explosive belts and various contraband items hidden under clothes.

There are a number of materials used in Pharmaceutical and Cosmetics industries which are fairly transparent in terahertz waves. This makes our THz imaging technology very attractive as a harmless non-destructive testing (NDT) technique for drugs, pills, medical products and baby’s diapers on industrial production lines. For instance, tablet manufacturers can use our high-speed terahertz imaging scanner at a speed up to 15m/sec for quality control (QC) to make sure every pouch in a tablet blister is properly filled with a tablet and that there are no empty blisters at the end of the process line. Paper, carton and plastic are common packing materials and completely transparent in THz light, which enables Terasense technology to ‘see through’ the package and identify all missing items.

Read more about terahertz applications in pharmaceutical industry

Perhaps more so than anywhere else, in the food and agricultural industries it is highly critical for quality control and inspection testing to avoid the use of ionizing radiation (X-rays) due to their detrimental effect on biological agents. This is where terahertz imaging technology, developed and commercialized by TeraSense, is extremely useful; for instance, checking if a robotic arm has put all candy bars into the carton, or checking for foreign bodies and insects inside of packaged food containers. Seeing through cardboard or PE packaging poses no problem to our THz imager. Checking the quality of various agricultural products like nuts and seeds also opens up huge perspectives for THz technology in this field too.

Read more about FOOD and about AGRICULTURAL applications.

The High-Speed Linear Terahertz Scanning system developed and manufactured by TeraSense for conveyor applications is a perfect solution for non-destructive testing and quality control of different materials in an industrial environment. One of the key benefits of the TeraSense THz imaging technology is its high sensitivity to different features and inclusions in the volume of non-metallic materials (ceramics, plastics, wood). Evaluation of density and humidity variations in the pressed powders (‘green tiles’ and kiln-fired tiles in the ceramic industry) is one of the most distinguished applications of the system, which has already been proved by factory tests!

A number of industrial NDT techniques, such as X-ray density scanning, infrared moisture sensors, visible light optical scanners and microwave kiln drying, employ separate parts of the electromagnetic spectrum to provide imaging of the wood in the wood processing industry. Yet despite the unique properties of the terahertz (THz) gap of the electromagnetic spectrum, THz imaging devices still do not top the list of wood-processing industrialists. However, there is no doubt that the high-speed THz imaging scanner solution from TeraSense is going to break the mold!

Detection of hidden defects in wood (which are difficult to detect using other technologies, e.g. color vision) is the first that comes to mind. Such defects may include, but are not limited to, knots, hollows, and foreign bodies like nails, screw and wormholes, and rotten as well as wet areas.

Research into new materials and semiconductor technology had expanded existing boundaries to the terahertz extremes, which opened doors for commercializing the THz technologies in numerous markets and various applications.

TeraSense’s technology shows promise in the automotive industry for such applications as detection of disrupted steel (and nylon) reinforcement and foreign inclusions inside rubber parts and detection of corrosion in coated metal parts.

Read more about terahertz-based imaging in automotive industry

Development of semiconductor technology and the research of new materials has expanded the utilized frequency limits to THz regions and opened doors for new applications in a number of industries such as wireless communication, homeland and personal security, medical diagnostics, FMCG packaging, food and wood processing, ceramic tiles production, and many more.

More recently terahertz technology has been used in only a few scientific applications in radio astronomy and lab research, and these terahertz systems were expensive and bulky solutions. Indeed, every research project has its specific requirements.

Some of the popular practical applications of our THz imaging cameras are beam profiling/measurement, which includes imaging of beams from TDS and FDS spectroscopy systems.

Researchers who are interested are welcome to read more about terahertz imaging for sciences